Development as a starting point

The Sales & Development department is the first and most important point of contact for you as a customer within Rena Castings. This starts as early as the development phase, in which you make your concept, your wishes and requirements known. The strength of Rena Castings is that we can convert these ideas and requirements into your ideal high pressure die cast component by means of in-depth engineering.

In our production departments, automation has been implemented to such an extent that the labour cost component is greatly reduced. This enables us to supply products at the lowest possible cost price.

Step 1: Product Development

In the concept phase, Rena Castings, in consultation with the client, generates ideas for the product to be produced and/or the composition of products. We do this in such a way that an optimum is created for you, the client, between manufacturability, functionality and the final cost. Our strength is that we can convert these ideas and requirements into your high pressure die cast component by means of in-depth engineering. In this way, we can save costs for you at an early stage! After all, a good design leads to optimal control of production costs.

Step 2: High Pressure Die Casting

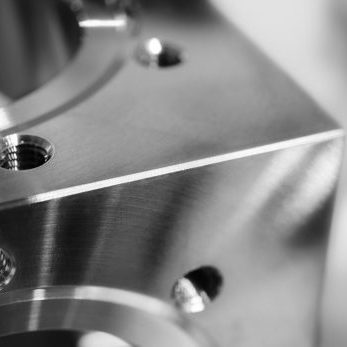

Step 3: CNC Machining

Our fully automated CNC machining centres and CNC lathes are used for precise machining and large series.

The mechanical machining of non-ferrous castings requires a specific approach. Due to the great freedom of shape of castings, only product-specific clamping tools are used.

For very large series, specific machining equipment is often developed, such as carousels with multi-spindle machining units.

Step 4: Assembly of Components

Rena Castings would like to supply products that are immediately ready to use for its customers and can therefore be installed in-line. Rena Castings has an assembly department in which value is added by carrying out complex assemblies and/or additional tests on the castings it processes. In this way, Rena Castings' customers purchase components with the required functionalities and against the requirements and quality standards set by them.

Step 5: Delivery and Aftersales

Rena Castings is an IATF 16949 certified company that delivers a complete PPAP archive upon delivery of your projects.

WANT TO KNOW MORE?

Our specialists will be happy to help you!