Rena Castings develops and produces die cast parts in aluminium and zinc alloy for the automotive industry, among others. The products are usually part of a larger and more complex assembly. Because of the high, technical requirements that are set for the parts, Rena Castings is usually already involved in the design phase of the products. By being involved early in the design phase, Rena Castings is able to control production costs, which leads to a competitive price-quality ratio.

Concept Development

In the concept phase, Rena Castings generates ideas, in consultation with the client, to give shape to the product or composition of products. We do this in such a way that an optimum is created for you, the client, between manufacturability, functionality and the final cost. Our strength is that we can convert these ideas and requirements into your high-pressure injection moulding component by means of in-depth engineering. In this way, we can save costs for you at an early stage! After all, a good design leads to optimal control of production costs.

3D Engineering

After the concept has been worked out, a 3D design will be made. Rena Castings works with the CAD software SolidWorks, with which all parts, materials, machining, unloading, parting lines etc. are designed. The final CAD product-file forms the basis for the creation of the die casting mould. If desired, Rena Castings can take care of the entire 3D design of the product for the customer.

Because of our extensive experience in designing die cast products and moulds, mould changes afterwards (extra costs) are a thing of the past.

Moulds and Fixtures

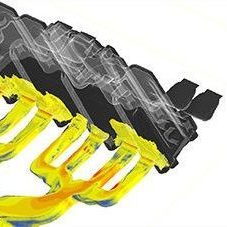

Rena Castings' toolmakers make moulds, trim dies and specific clamping tools. The construction of die casting moulds is laid down in our mould conditions. Based on the customer's specific requirements, each tool is designed in 3D and then built. Furthermore, various calculations are carried out in order to realise at an optimal die cast product. These casting technical calculations consist of:

- Casting process: calculations of speeds, pressures, closing force, etc.

- The mould: calculations of quantity of materials, thickness of the runner, cutting, cycle time, type of cooling medium, heat management, etc.

Meer weten?

Onze specialisten helpen u graag verder!