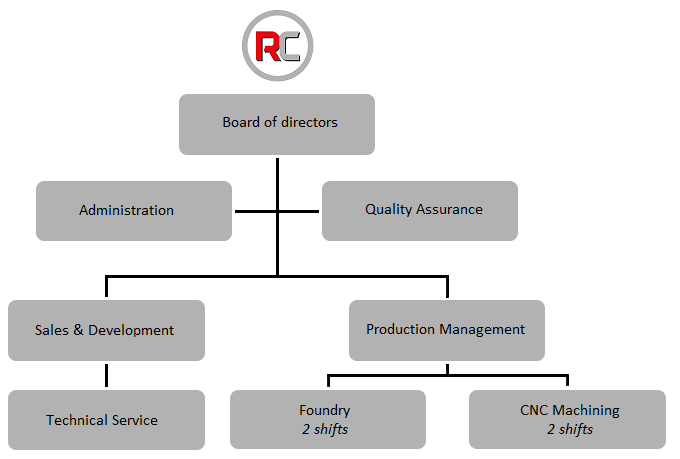

Organisation

The organisation of Rena Castings B.V. consists of approx. 50 employees. About 35 employees work in the automated high-pressure die casting, automated CNC machining and the logistics departments. The Technical services department provides technical support and manufacturing of production tools, with 4 employees. The Sales & Development department, in cooperation with the Technical Services Department, takes care of an important part of the production automation. Production Management takes care of the operational activities within the organisation. The Sales & Development, Financial Administration and Quality Service departments also act as support services. Under the leadership of the Board of Directors, the policy and strategy are determined in a 6-member Management Team.

Managing Director: I. Crooijmans MSc

Director: Dr. Ir. M. Crooijmans

Commercial and Technical Director: Ing. E. Vijfvinkel

Head of Production: I. Crooijmans MSc

Head of Logistics: I. Crooijmans MSc

Head of Sales & Development: Ing. E. Vijfvinkel

Head of Projects: Ing. R. Kurvers

Head of Quality: Ing. A. Grubben

Head of Administration: C. van Bekerom

Sales & Development

The Sales & Development department is the first and most important point of contact that you, as a customer, have within Rena Castings. This starts as early as the development phase, in which you make your concept, your wishes and requirements known.

The strength of Rena Castings is that we can convert these ideas and requirements into your high-pressure die casting component by means of in-depth engineering.

We can save costs for you at an early stage!

"After all, good design leads to optimal control of production costs."

Sales & Development remains your central point of contact within Rena Castings. This applies to the quotation process, but also during the entire technical realisation of your new product. Short, clear lines.

We ensure the right communication with our toolmakers, the various production departments and our logistics centre. At the end of the line, you can expect a solution that fully meets your specific requirements!

Your Sales & Development contacts have an excellent technical background. They specialize in our processes and therefore know exactly what the possibilities are with regard to your product and its production.

Quality

At Rena Castings, we are proud of our IATF-16949 certification, a globally recognised standard for quality management in the automotive industry. As part of this certification, we also comply with the ISO-9001 standard. This ensures that we meet the highest quality standards and continue to strive for excellence in everything we do.

Every year, we have ourselves audited by LRQA. Parts for the automotive industry, after completing the PPAP, are produced according to IATF-16949 quality regulations.

The quality department has, among other things:

- Two advanced 3D measuring machines (Mitutoyo Euro-C-A544) with a measurement accuracy of 0,001mm.

- Spectral analysis device

- X-ray device 5-axis including image processing software

- Hydac contamination test unit (for cleanliness measurements)

- Differential pressure leak test equipment

In the project phase, the checks that have to be carried out during the production process are determined together with the customer. These are related to risks with respect to related to functionality, durability and cosmetic requirements. In order to categorize the risks, we always make an FMEA during the project phase.

Certificates

As part of the IATF-16949 certification, we also comply with the ISO-9001 standard.

IATF 16949:2016

DAF 10 PPM Award

WANT TO KNOW MORE?

Our specialists will be happy to help you!